Even if the structures of co-current flow and of counter-current flow plants are very similar, their behaviour in non-nominal or perturbed conditions can significantly differ. unpicked product at the end of the first conveyor or not completely filled boxes. Undesired perturbations in the product flow rate from its nominal value can lead to critical events, i.e. Depending on the relative movement of the two conveyors, the plant operates in co-current or counter-current flow configuration. The typical configuration of these packaging plants consists of a set of sequential robot stations, performing pick-and-place cycles from one conveyor to another parallel one, which transport the products and the boxes to be filled. The aim of secondary packaging plants is to pick food products from a conveyor belt and to place them into boxes. Finally, some recommendations are given regarding the type of material to be used in pressure sensors for engineering applications, particularly in the biomedical field. Materials such as piezoresistive fabric or ink show to be suitable for applications where deformation and flexible sensors are required, Velostat is the least accurate but suitable for basic applications and in which a high resolution is not needed. A time drift test with a dead load was also performed for evaluating stability. The repeatability and hysteresis of each sensor were evaluated in a response to load test realized several times. Furthermore, a comparative technical study including a commercial sensor as a benchmark is done with the aim of selecting a suitable material when measuring contact pressure.

This paper describes the fabrication of three different sensors using piezoresistive materials. These sensors are fabricated with materials that have certain properties such as piezoelectricity, piezoresistance and variable capacitance however, the most used characteristic is the piezoresistive effect.

They are used in characterization of vehicle tires, bearings, wind tunnels, prosthesis design, ergonomic analysis among other areas. The use of contact pressure sensors has become popular in various engineering disciplines in recent years.

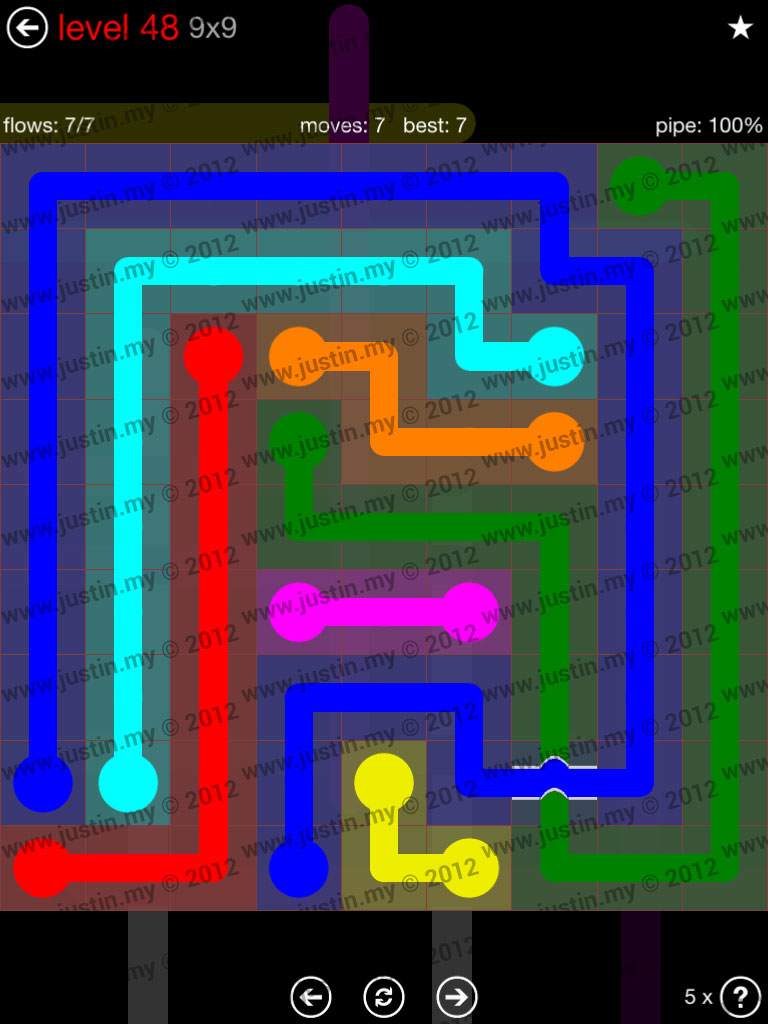

FLOW FREE BRIDGES 9X9 LEVEL 26 SKIN

The flexible sensor can be directly mounted onto human skin for detecting mechanical motion, exhibiting its great potential in wearable electronics and human–machine interfaces. Due to the advanced mechanical design of the metallic electrode, the strain sensor shows excellent mechanical tolerance to pressing, bending, twisting, and stretching. The device exhibits high sensitivity (the absolute value of the resistance change rate under a testing strain level, 26) and good mechanical stability (surviving ~hundreds of cycles of repeated stretching). In this work, we introduce a soft, skin-integrated strain sensor enabled by a ternary elastomer composite of graphene/carbon nanotube (CNT)/Ecoflex, providing a low-cost skin-like platform for conversion of mechanical motion to electricity and sensing of human activities. Flexible electronics exhibit tremendous potential applications in biosensing and human–machine interfaces for their outstanding mechanical performance and excellent electrical characteristics.

0 kommentar(er)

0 kommentar(er)